The X-Q42 series aluminum bar shearing machine production line produced by our company is the ideal cutting equipment for high-efficiency cold cutting aluminum bars. It is mainly used for cutting various aluminum profiles. It adopts the cutting process of less cutting no cutting raw materials. The equipment has the advantages of low energy consumption, high efficiency, small material consumption high cutting quality. The ratio of working hours to single sawing is 1:20, the material utilization rate is increased by 2 This series of products have reliable performance convenient maintenance. It is an ideal shearing equipment for bearing, forging, metallurgy other industries. It is also an energy-saving material saving equipment promoted by the state.

The production line of X-Q42 Series bar shearing machine mainly includes the following structures:

1. Automatic feeding, feeding mechanism, feeding system includes automatic feeding automatic feeding. The automatic feeding part includes a material storage machine, a sliding material rack an automatic turning material feeding device.

2. Main engine part: the rectification of the main engine includes automatic cutting, automatic lubrication of the main engine, automatic alarm of insufficient air pressure, automatic alarm of oil shortage of automatic lubrication, automatic alarm of oil pipeline blockage.

The frame is an integral welded steel plate structure with sufficient strength rigidity. When the bolt in the left side of the machine tool frame is loosened, the bolt in the left side of the machine tool frame can be quickly pulled out to change the angle of the blade.

3. Automatic pressing mechanism: the pressing mechanism is driven by air cylinder, which can effectively fix the bar on the shearing die base by using the pressure boosting principle of the force increasing eccentric pressing mechanism, so as to improve the shearing precision quality of the bar, the action of the pressing mechanism is sensitive reliable.

4. Transmission system: the bar cutting machine adopts two pole upper transmission. The first stage drive is belt drive, the second stage drive is gear drive.

5. Lubrication system: lubrication is an important means to ensure the normal operation of equipment avoid unnecessary grinding damage of various parts. The lubrication system includes electric centralized lubrication manual decentralized lubrication. The lubrication time is controlled by PLC.

6. Sizing mechanism: the sizing mechanism can determine the length of the material to be cut. According to the process requirements of the material, preliminarily determine the size of the retaining material for trial cutting, check whether the cutting weight meets the process requirements, adjust it until it is appropriate.

7. Automatic shear electrical system, according to the automation requirements, the production line needs to reconfigure the electrical system, mainly including the detection control of each action signal transmission, mainly using PLC centralized intelligent control to achieve command the cooperation of various organizations, so as to achieve the purpose of automatic shearing.

This system adopts Mitsubishi PLC, high quality electrical components, long life, stable reliable performance.

The production line of X-Q42 series aluminum bar shearing machine has the following characteristics:

1. The main frame is an integral welded structure with enough strength rigidity.

2. The transmission is two-stage up drive, stable transmission low noise.

3. The sliding block adopts rectangular inlaid steel guide rail, which has good wear resistance good precision retention.

4. Side draw type quick change blade mechanism, safe, quick labor-saving.

5. Combined pneumatic friction clutch brake, flexible reliable operation, convenient maintenance.

6. The pressure increasing pressing mechanism has large pressing force is safe reliable.

7. This series of products have automatic feeding, automatic cutting automatic counting. At the same time, it has the functions of automatic alarm of insufficient air pressure, abnormal lubrication display alarm, material blocking protection, etc.

8. The minimum shear length is 50 mm;

9. Only one person is required to be on duty for the whole line, which saves labor reduces labor force;

10. The transmission is a two-stage up drive with stable transmission low noise;

11. The slope of cold shear section ≤ 3 °;

12. Weight error ± 0.5%

The main parameters of X-Q42 series aluminum bar shearing machine production line are as follows:

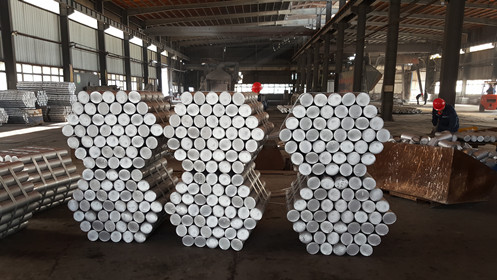

The material section cut by precision Shearer

The X-Q42 series aluminum bar shearing machine production line produced by our company is the ideal cutting equipment for high-efficiency cold cutting aluminum bars. It is mainly used for cutting various aluminum profiles. It adopts the cutting process of less cutting no cutting raw materials. The equipment has the advantages of low energy consumption, high efficiency ……