Q11Y series mechanical swing plate shears use moving upper blade fixed lower blade, adopt reasonable blade clearance. The tool carrier moves along the vertical line. Since there is no forward inclination angle, the section of upper blade must be processed into diamond, the cutter head swings along the arc line. The cutting blade section surface should be processed into diamond, so there are only two blades. Since the upper blade inclines forward slightly in the shearing process, The shearing force is applied to the metal plates of various thicknesses to make the plates break separate according to the required size.

Q11Y series mechanical pendulum plate shears are composed of bed, tool rest, transmission, clutch brake, pressing material, blocking material, lubrication other parts. The bed is of high quality steel plate welding structure, with good rigidity high strength.

Main structural features

1. The machine body adopts all steel plate welding structure, which can effectively eliminate the stress by vibration aging annealing, so as to ensure that the machine tool has high static dynamic stiffness shock absorption performance, that the accuracy of the machine tool can be maintained for a long time.

2. The sliding block (upper tool rest) is an integral welding structure of plate weldment. The swing shear movement is realized within a certain angle range around a fixed circle center through the transmission of connecting rod crankshaft; the blade clearance is adjusted to worm gear structure, the scales are set on both sides of the bed respectively, the zero position limit function is also provided. The blade clearance can be adjusted within 2-3 minutes.

3. The transmission system adopts the first-class belt drive the second-class gear drive, with reasonable transmission layout convenient maintenance. In the process of shear transmission, it has shear overload protection function to prevent overload shear workpiece damaging the equipment.

4. The structure of the machine should be compact, its main principle is composed of motor → flywheel → clutch / brake (friction type) → gear mechanism → spindle → upper lower movement of upper tool rest; traction electromagnet hydraulic drive clutch is adopted; the friction plate of clutch brake is required to domestic famous products with reliable quality.

5. The equipment should have a strong mechanical pressing system, the pressing force should be large enough, there should be no movement of sheet metal during shearing. The fence type safety protection device is installed at the pressing system to prevent the operator entering the cutting edge by hand.

6. The transmission rotating parts are equipped with safety protection cover to ensure that the safety performance of the equipment meets the national requirements.

7. The blade material can meet the following plate shear: carbon steel, 1Cr20Ni14Si2, 0cr23ni13, 1Cr18Ni9Ti. The blade is delivered after flaw detection.

8. The double button switch controls the shearing operation has the functions of inching, single operation continuous operation. It is equipped with safety protection device of electrical interlocking, which meets the national safety standard.

9. It is equipped with infrared ray line-up device, which is convenient for scribing shearing.

10. Centralized automatic control is adopted for equipment lubrication, which is composed of oil pump, distribution valve pipeline. If there is oil shortage in lubricating parts, automatic alarm will be given. The lubrication is manual multi-point dry oil pump lubrication, the oil distribution can be completed by the oil separator, the lubrication performance is reliable.

11. Cam oil pump pressure device, through the cam pump body piston movement to achieve the pressure action. Eight pressing feet are installed on the bed (above the worktable), the pressing force can be adjusted according to the thickness of the shearing plate, so as to ensure reliable compaction shearing accuracy.

12. Manual blocking device, the baffle plate can be lifted up to realize longitudinal infinite shear.

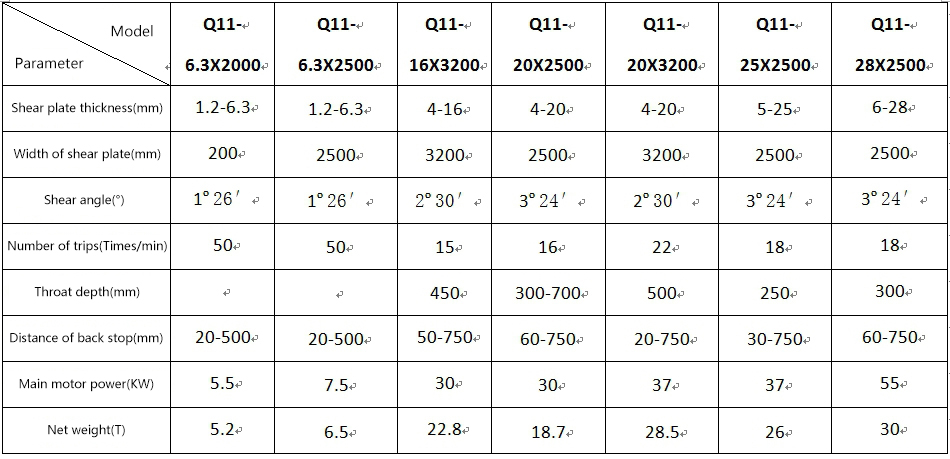

Technical parameters of Q11Y series mechanical tilting plate shears

Q11Y系列液压摆式剪板机是借于运动的上刀片和固定的下刀片,采用合理的刀片间隙,刀架沿着垂线运动,由于没有前倾角,因此上刀片断面必须加工成菱形,刀架沿着圆弧线摆动,剪切刀片断面宜加工成菱形,故只有两个刀刃,由于上刀片在剪切过程中略有前倾,对各种厚度的金属板材施加剪切力,使板材按所需要的尺寸断裂分离。

Q11Y系列液压摆式剪板机本机床由床身、刀架、传动……