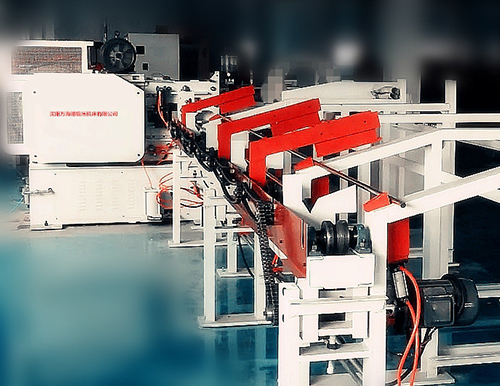

The production line of precision bar shearing machine is suitable for precision shearing, with high shearing precision "0" loss of saw edge. The production efficiency is high, the shearing speed is more than ten times that of the band sawing machine, the workpiece precision is three times higher than that of the common bar cutting machine, the material saving energy saving effect is very remarkable.

For example, cutting 45 ා hot rolled steel:

1. Section inclination: ≤ 1.5 °;

2. Weight error: ≤ 0.5%

3. Roundness of section: ≤ 96%

Structure features of x-q45 series precision bar shearing machine production line:

1. Using the principle of constrained shearing, the shearing accuracy is greatly improved.

2. Automatic shearing is realized by PLC control, the shearing quality is stable reliable.

3. High degree of automation, the whole line to achieve automatic feeding, automatic feeding, automatic timing, quantitative lubrication, automatic cutting, automatic counting other functions.

4. The electrical system has the following production lines: automatic length adjustment, automatic statistics, automatic start stop of feeding mechanism, frequency conversion speed regulation, double pressure roller feeding, rotary encoder technology, automatic sorting of finished materials waste materials, man-machine interface, high-speed shearing technology, special material blocking receiving technology.

5. Adopt the following components to ensure the reliability of the system:

PLC system: adopt German Siemens Japan Mitsubishi technology;

Pneumatic system: adopt the pneumatic component technology of Taiwan Yadeke Wuxi Huatong;

Lubrication system: Zhejiang flow technology is adopted. There are motor overload alarm, lubrication cycle indication alarm air pressure insufficient alarm;

6. It is equipped with material receiving mechanism to cut long material to prevent material sagging;

7. The anti warping mechanism is provided to prevent the tail warping;

8. The friction plate of small-sized products can be quickly replaced, the friction blocks of large-sized products can be adjusted changed quickly.

The equipment is also equipped with anti shock noise reduction measures, so it is very convenient to use maintain. In recent years, precision shearing technology has developed rapidly. X-q45 series precision bar shearing machine production line is suitable for cutting Q235A, 20Cr, 10 ᦇ, 08,45 ᦇ, 70 ᦇ, 40Cr, 42CrMo, 60Si2Mn, 23MnNiCrMo54, 20CrMnTi, etc. It can meet the needs of domestic users.